ELMER'S MOLD SERVICES

LINE GRAIN FINISH

We are continuing to expand our capabilities to clients needs. Our "tool belt" always has one more spot to add on.

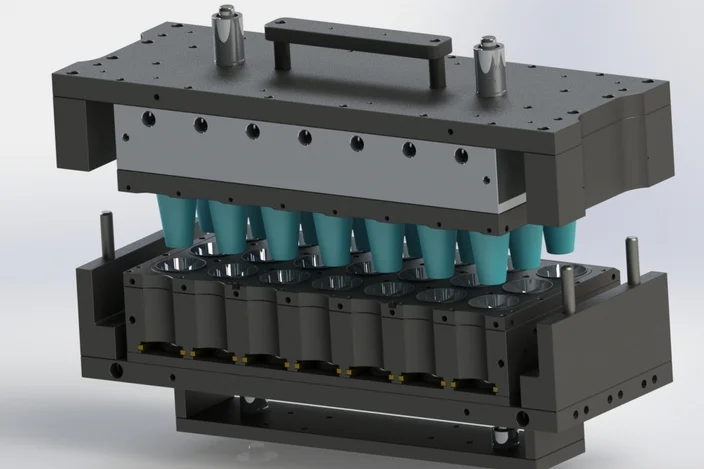

Mold Types

You can send us your 3D CAD/PDF file for RFQ

Compression

Plastic Injection

Vacuum Forming

Stamps

Extrusion Dies

Blow Molding

Molds (per half) up to 6,000 lbs forklift capacity

Mold Repairs

Flashing /Damaged Shut offs

Dinged, Gouged, damaged mold surfaces

No-weld precision peening (where applicable)

Replace/Fix broken springs, leader pins, ejector pins, sprues, slides, any plates, screws/bolts (broken in) etc...

SPI FINISHES

Type A includes A1, A2, A3 and the highest as Optical Finish (Mirror Finishes)

Type B includes B1, B2, B3

Type C includes C1, C2, C3

Type D uncludes D1, D2, D3

Textured Finishes

Garnett/Glass blasting media from 16grit up to fine glass bead.

Soda Blasting

Plastic Media

Silicon Carbide

Virtually any media can be had to order, we match most Mold Tech textures as well.

Line grain finishes on all material types

Welding

MIG/TIG Aluminum and Steel (Hobart)

Precision Micro Welding

Machining

Precision Sherline Mini Lathe

Chevalier Manual Milling Machine

GMC High Speed Precision Lathe 16" X 40"

Central Machinery 20" Drill Press

Quick resources forfull CNC capabilities

Industry Sectors

Aerospace

Chemicals

Electronics & Miscellaneous Technology

Government/Public Sector